With the continuous advancement of the urbanization process, the construction of tunnel engineering is becoming more and more important. In tunnel engineering, hydraulic rock drills, as an efficient and reliable tool, are widely used in rock crushing and rock drilling operations.

Drilling of rock is an inevitable step in tunnel construction. Traditional rock drilling methods require a lot of manpower and time, and are inefficient and laborious. The application of hydraulic rock drills has changed this situation and greatly improved the efficiency and quality of rock drilling operations.

First of all, the hydraulic rock drill has the characteristics of high rock drilling efficiency. Its rock drilling cutters can quickly and effectively break and drill rocks through the high pressure provided by the hydraulic system. Compared with traditional rock drilling methods, hydraulic rock drills can complete a large number of rock drilling operations in a relatively short period of time, improving work efficiency.

Secondly, the hydraulic rock drill has the characteristics of strong adaptability. In tunneling, rock types and hardness vary, and traditional rock drilling tools are often unable to cope with the different situations. The hydraulic rock drill can choose the appropriate rock drilling cutter according to different rock types and hardness, so as to adapt to different rock drilling needs. This makes rock drilling operations more flexible and efficient.

Finally, hydraulic rock drills have lower noise and vibration during rock drilling. In tunnel engineering, noise and vibration will have a certain impact on the surrounding environment and workers. The hydraulic rock drill effectively reduces the noise and vibration by reducing the friction and impact between the tool and the rock, and improves the comfort and safety of the working environment. To sum up, the hydraulic rock drill, as an efficient and adaptable tool, has shown obvious advantages in the application of tunnel engineering. It not only greatly improves the efficiency and quality of rock drilling operations, but also reduces the impact of noise and vibration on the surrounding environment and workers. It is believed that with the continuous advancement of technology, the application of hydraulic rock drills will play a more important role in tunnel construction and provide strong support for urban development and traffic construction.

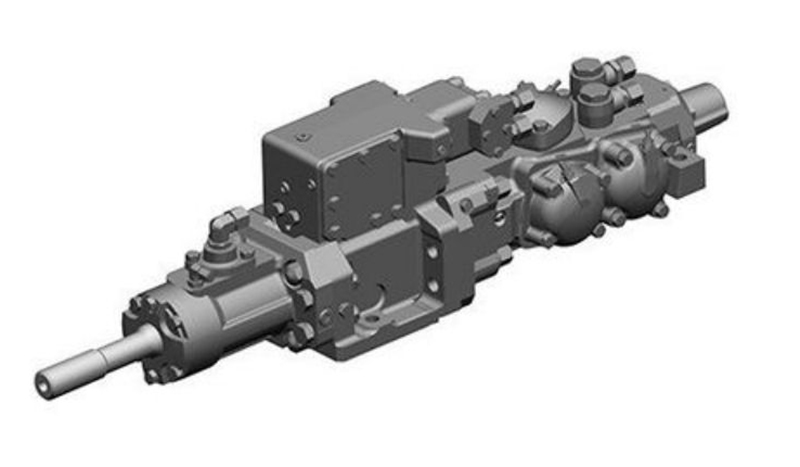

A hydraulic rock drill is a device that uses the pressure of a liquid to transmit energy for rock breaking and rock drilling operations. It has the following main components:

Hydraulic system: The hydraulic rock drill uses liquid (usually hydraulic oil) as the power transmission medium. The hydraulic system consists of hydraulic pumps, hydraulic cylinders, pipelines and control valves. The hydraulic pump is responsible for pumping hydraulic oil from the oil tank, pressurizing it, and then transmitting the pressure to the hydraulic cylinder through the pipeline.

Hydraulic cylinder: The hydraulic cylinder is the power actuator of the hydraulic rock drill, mainly composed of a piston, a piston rod and a cylinder. When the hydraulic oil enters the hydraulic cylinder, the piston is pushed forward by the hydraulic pressure, thereby driving the rock drilling tool for crushing and rock drilling operations.

Rock drilling tools: The rock drilling tools of hydraulic rock drills are usually composed of rock drilling bits, rock drilling plugs or rock drilling ball heads. Rock bits are for harder rock, rock plugs are for concrete structures, and rock balls are for more extensive rock drilling.

The working principle of the hydraulic rock drill is to convert the pressure of the hydraulic oil into a higher force through the hydraulic system, and then transmit it to the rock drilling tool. When the hydraulic oil enters the hydraulic cylinder, the piston is pushed forward by the pressure, driving the rock drilling tool to impact and cut the rock surface. This impact and cutting action converts the point-like force on the rock surface into a planar force, thereby achieving rock breaking and rock drilling.

The hydraulic rock drill has the characteristics of high rock drilling efficiency, wide operation range and strong applicability. It can adapt to different types of rocks, including granite, limestone, sandstone, etc., and can also be applied to various engineering scenarios, such as tunnel construction, mining, mountain demolition, etc.

In addition, the operation and maintenance of hydraulic rock drills are also very important. Before using a hydraulic rock drill, the operator needs to understand the equipment’s instruction manual and receive relevant training. The operator should operate the equipment reasonably according to the specific rock drilling needs and working environment, and abide by the safe operation rules. At the same time, regularly maintain the equipment, such as replacing worn tools, checking and repairing the hydraulic system, etc., to ensure the normal operation of the equipment and prolong its service life.

a hydraulic rock drill is a device that converts the pressure of hydraulic oil into power through a hydraulic system to achieve rock breaking and rock drilling operations. It has the characteristics of high efficiency and strong adaptability, and is suitable for various types of rocks and engineering scenarios. The operator should abide by the operating procedures and perform regular maintenance and maintenance on the equipment to ensure the working effect and safety.

Post time: Aug-18-2023