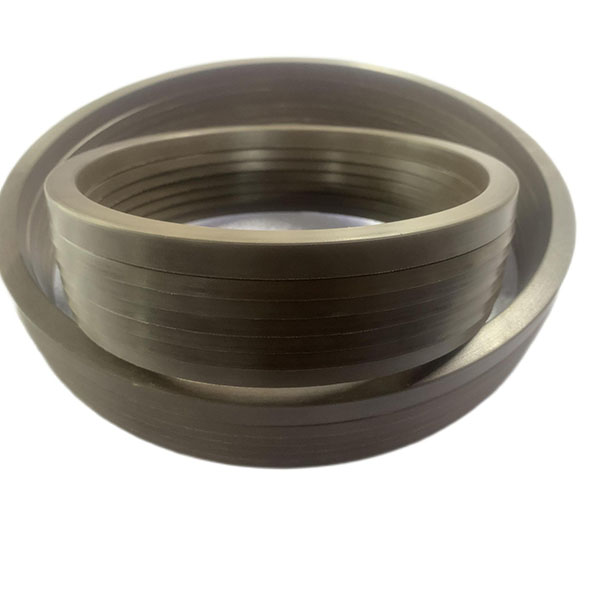

V-shaped combined seal

Product video

Scope of application

Pressure: ≤ 400bar

Temperature: - 40~100 ℃

Linear speed: ≤ 0.5m/s

Even under harsh working conditions, V-ring seals are extremely suitable for sealing plunger, piston rod of press, oil cylinder, valve shaft and valve core. Therefore, these seals can be recommended to be used under unpredictable actual conditions.

Working Medium

Hydraulic oil, lubricating oil, grease mineral oil

For high-temperature and chemical resistant working conditions, please contact our customer service department to recommend more suitable materials and structures to you.

Features

The elastic seal ring and V-shaped ring fully act on the pressure surface with the help of the liquid working pressure, so that the working seal lip can be well expanded, and the sealing surface of the cylinder barrel and piston can be pressed to achieve the sealing purpose.

1. The number of sealing rings can be selected according to the pressure;

2. Allow certain eccentric load and eccentric movement;

3. In the process of use, if the V-shaped combined seal ring leaks, the sealing effect can be obtained by adjusting the pressing mechanism to press again;

4. When the packing cannot be loaded axially, it can be cut for use. During installation, the cut shall be staggered by 90 degrees;

5. The surface roughness value of the coupling surface of the sealing element can be larger than that of the coupling surface of the sealing element;

6. No anti-extrusion measures are required for use under high pressure.

Installation

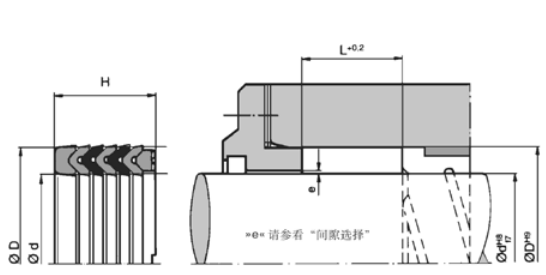

Because the elasticity of the fabric V-ring seal is very low, and this kind of seal requires axial direction Preload, so there is an open installation groove on one side.

It is usually consistent with the groove length "L". Manufacturer of seals and metal parts The difference (especially in the case of large size) can be compensated by clearance plate or ring head screw Compensation to get the best function (at least 5% of the length "L" can be adjusted). When subjected to The flexibility of the seal will actually decrease when it is squeezed strongly. At this time, it will accompany With excessive friction and large wear, the piston rod is guided by the support ring.

Use. Because of this adjustability, such components can be used in special occasions, such as In the case of high speed, wide temperature range and large pressure change,or these parameters In both cases. Each element of this seal shall be grouped according to its The parts shall be installed one by one in sequence. Add some lubricating oil or grease slightly.

It will make assembly much easier. Fabric V-ring seal with large cross section can be used at Rub it slightly with hot lubricating oil to make it more soft, and then install it It's very convenient. For easier maintenance, these seals can also be cut. V The O-ring seal and retaining ring are cut at 45 ° angle, while the support ring is cut at 90 ° angle. Elements The cut of the groove shall be staggered at 120 ° during installation, so as not to change the length of the groove Degrees.